Here are some completed projects through the approval of the concerned companies

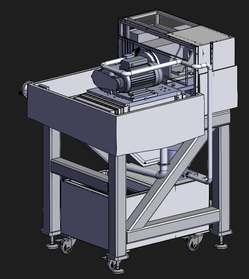

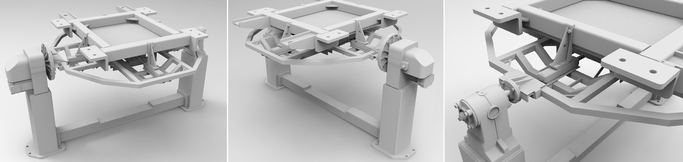

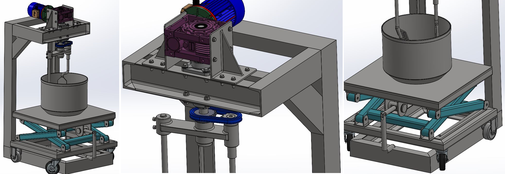

Design and 3D construction of a vibration tester

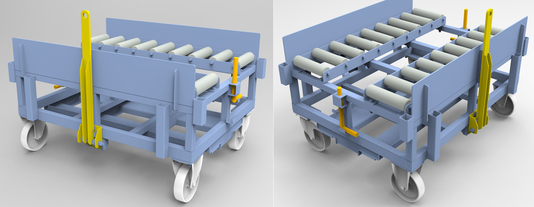

Design and 3D construction of a transport trolley

3D design of an assembly system

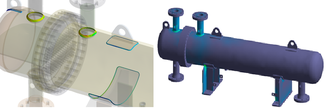

FEA of a chiller incl. reports for TÜV approval

- Pressure tank verification in accordance with AD2000 and DIN 13445

- Verification (weld seams + bolts + weld frame) according to Eurocode 3 (DIN 1993)

- Extraction of critical natural frequencies for seismic verification

- Vibration analysis

- Report

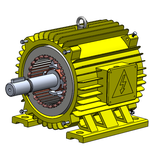

Electromagnetic simulation E-Motor

-Analysis of Vibration and noise

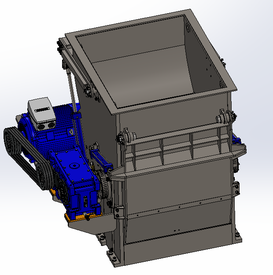

3D Design a shredder

FEA of a chiller with compressor

- Pressure tank verification in accordance with AD2000 and DIN 13445

- Verification (weld seams + bolts + weld frame) according to Eurocode 3 (DIN 1993)

- Extraction of critical natural frequencies for seismic verification

- Vibration analysis

- Report

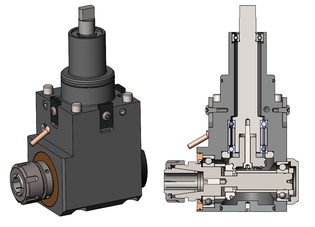

Design of a Drilling device

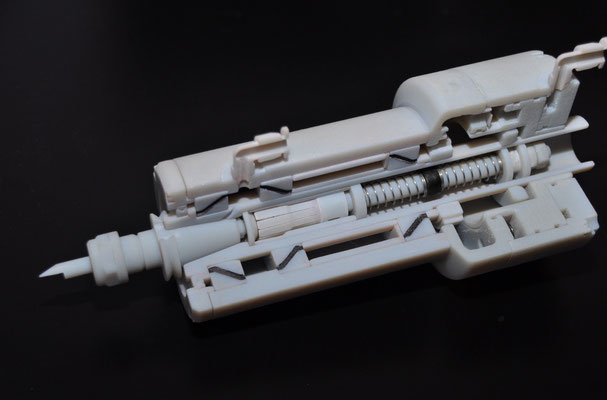

Design of a Tool change spindle

Design of a Machine to remove Nickel

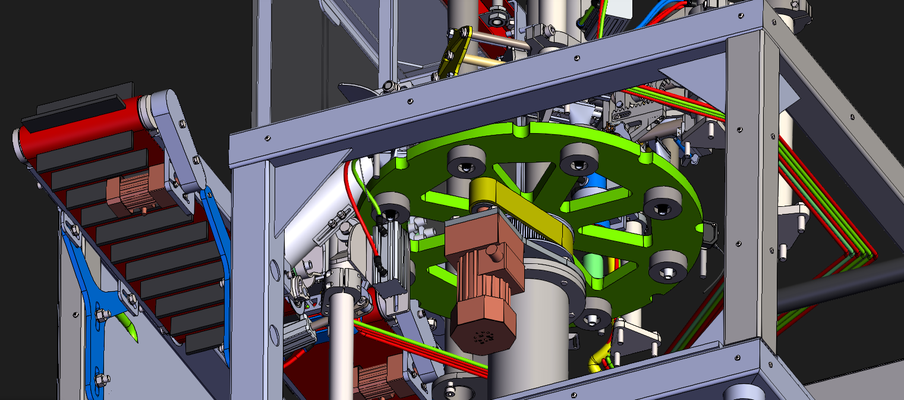

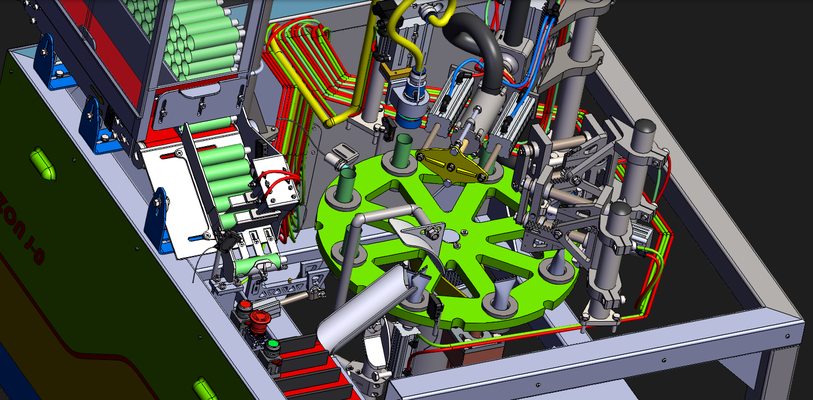

Design of a welding rotary table

3D design of a production cell

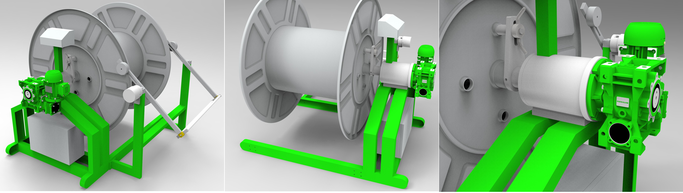

3D design of a winding machine

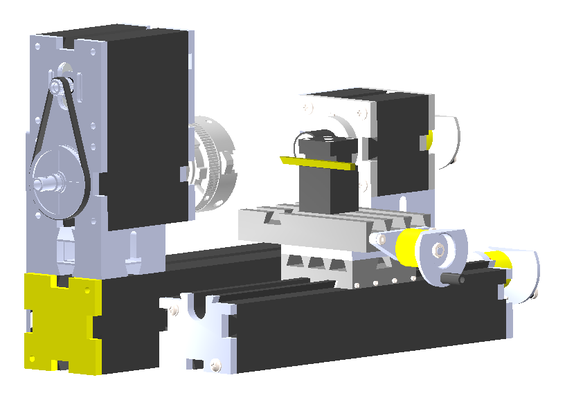

Design of a mini lathe

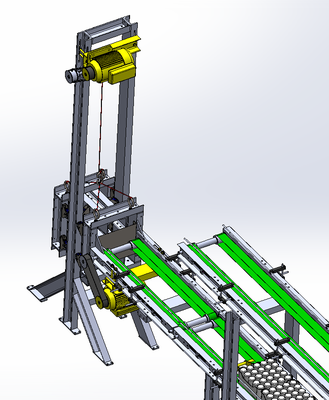

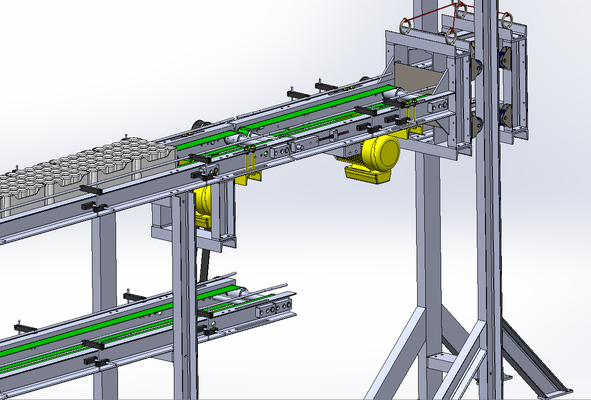

construction of belt conveyor

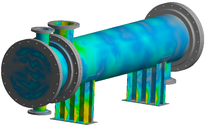

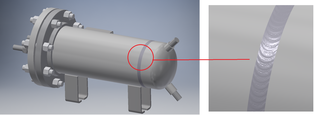

Numerical validation of a heat exchanger incl. weld seam calculations (AD2000, EN 13445, EN 12952-53)

- Strength calculations of the assembly incl. partial simulation of the individual parts (iterations)

-Weld calculation and attachment (iterations)

- Determination of critical points on assembly and individual parts

- Evaluation of stresses and deformations according to standards

- calculation report for TÜV

Stent Design + FEA

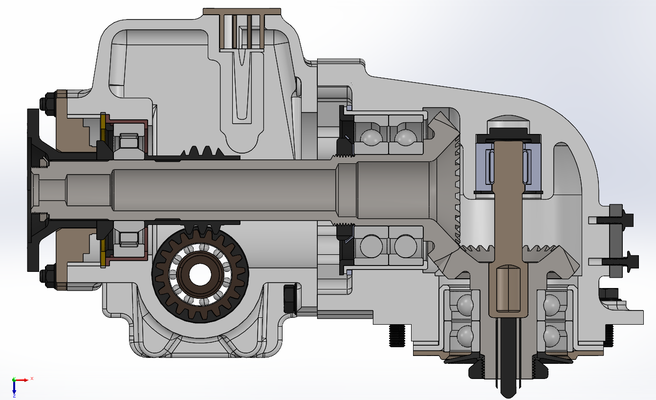

Gearbox design

3D Konstruktion einer Schwenkmaschine zum Schweißen

Design optimisation of a planetary lab mixer

construction of a Automatic processing equipment for intersecting line

Strength calculation of Crane trolley

Construction and strength calculation of a gantry crane according to steel construction standards

Dimensioning and Strength analysis of folding engine crane

Strength analysis of an injection nozzle according to FKM and DIN EN 13445

Development of a connecting element

Calculation of the strength of a chiller (Eurocode 3, DIN EN 13445) and Anchor loads

- EARTHQUAKE SIMULATION (PARTS STRENGTH + ANCHOR LOADS)

- DEAD LOADS (PARTS STRENGTH + ANCHOR LOADS)

- OPERATING LOADS (PARTS STRENGTH + ANCHOR LOADS)

Investigation of the strength and dynamics of a mini lathe in operation (steel construction and mechanical engineering standards)

Dimensioning of a heat exchanger with weld design according to AD 2000 and DIN EN 13445

constant development, design and simulation of various implants

- HEART VALVES (STENTS) OR HEART VALVE SUPPORT FRAME

- STENTS AND VASCULAR PROSTHESES

- DENTAL IMPLANTS

- SURGICAL INSTRUMENTS

Numerical qualification and validation of a heat exchanger for approval by proof of fatigue strength and earthquake proof

-VALIDATION OF ALL WELDS ACCORDING TO EUROCODE AND DIN 13445

-SELECTION OF SCREW CONNECTIONS ACCORDING TO CUSTOMER REQUIREMENTS AND ACCORDING TO DIN EN 1993

PROOF OF FATIGUE STRENGTH of screws according to DIN EN 1993

Development, design and calculation of a maintenance platform

Optimization of bicycle test bench